Battery Lines

CANLINE offers comprehensive solutions for various battery production lines, including expertise in electric vehicle battery lines. As a top supplier with extensive expertise in the design and installation of conveying and handling systems for the metal packaging industry, we are leveraging our innovative solutions in the dynamic automotive and battery sectors.

Electric Vehicle Battery Solutions

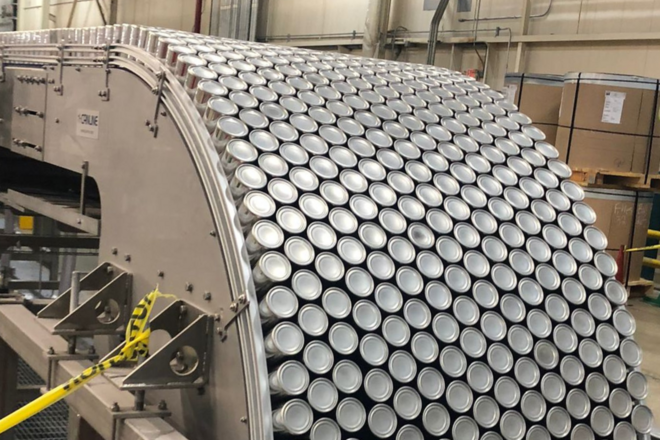

CANLINE offers customized electric vehicle battery solutions. We leverage our expertise in can manufacturing to tailor our conveying systems specifically for cylindrical battery cells. With our expertise in handling steel products using magnetic force, we have developed specific knowledge in conveying steel hard-case batteries. Collaborating with our partners, we've established standard concepts for producing individual cells and handling battery packs.

Batery Cell Case Manufacturing in Europe and USA

CANLINE is dedicated to advancing battery cell case handling, utilizing cutting-edge technology to provide effective solutions. With a proven track record in successfully manufacturing battery cell cases for Li cell production in Europe and the USA, we specialize in cylindrical battery case production, magnetic conveying, and standard battery pack conveyance concepts. Our focus is on offering efficient solutions and working collaboratively to meet your battery production needs.

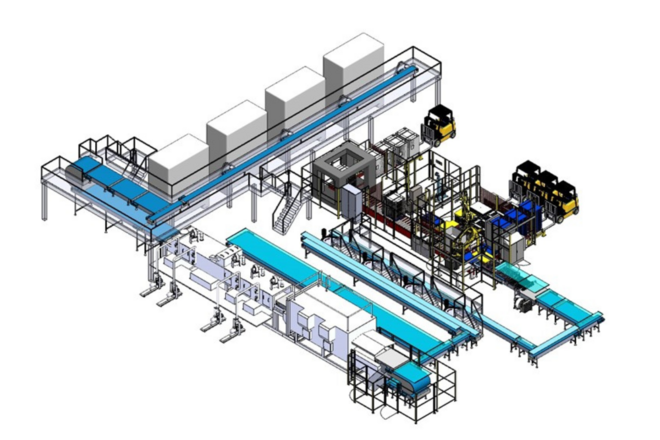

Seamless Machinery Integration

At CANLINE, we prioritize customer satisfaction and building long-term partnerships. Our expertise spans high-speed automation, seamless machinery integration, and maintaining top-line efficiency. Our modular concept ensures quality requirements are met, while full line control and market-leading technology contribute to our customers' success.

CANLINE's Battery Line Services

1. Cylindrical Battery Case Production: We specialize in manufacturing cylindrical battery cases.

2. Magnetic Conveying of Single Cells and in Mass: We offer expertise in efficient magnetic transportation of individual battery cells and mass quantities.

3. Standard Concepts for Battery Pack Conveying: We design and implement conveyor systems for the smooth movement of assembled battery packs.

4. Solutions for Prismatic Cells and Packs: Within the business unit of Industrial Solutions of the XANO Group, CANLINE specializes in providing solutions for prismatic cells and packs.

5. Line Control, Onsite Maintenance, and Line Care Solutions: We offer services for optimizing production processes, maintaining equipment, and ensuring smooth production line operation.

Case Study: Integrated Conveying and Buffering Systems

We recently tackled a challenge from a customer who needed high-speed conveying and buffering systems integrated into their EV battery cell production lines in Europe and the USA. The customer's top-level concerns included high-speed operation, gentle handling, flexibility, maintaining a clean environment, and rigorous product quality checks.

The Solution

Our handling solution met all requirements effectively. It led to a substantial increase in manufacturing output, resulting in significant cost reductions for the customer. Full automation was key, allowing for high-speed mass production while minimizing labor intensity. Consistent quality was achieved through a continuous flow philosophy and innovative techniques. The end result was a highly flexible solution suitable for multiple production floors, ensuring gentle and clean handling of cylindrical cells at maximum speed.