Line Control

Even the highest quality of your conveying equipment is no guarantee of a successful line. Success hinges on the inclusion of high-quality, user-friendly controls. With the integration of such controls your production line will provide the efficiencies necessary to outperform your competitors. CANLINE's Line Control department, collaborating closely with our mechanical and magnetic engineers, ensures that the controls are tailored precisely to meet the line's requirements.

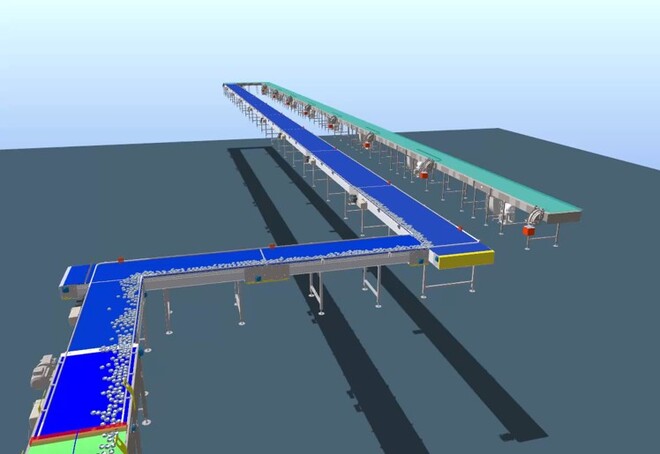

Simulation and Emulation

CANLINE uses simulation and emulation technologies to test and optimize the functionality of the automation solution before production and installation. These tools help us to make our customer familiar with our system before we start commissioning. Maximum customer consent is guaranteed and it enables us to reduce commissioning time by up to 50% and ensure a smooth start-up process.

Data Analysis and Industry 4.0

CANLINE's automation solutions are designed to be flexible and adaptable to the changing needs of the industry. Data analysis, artificial intelligence (AI) and Industry 4.0 concepts are helpful to optimize the performance of our conveying and handling solutions.

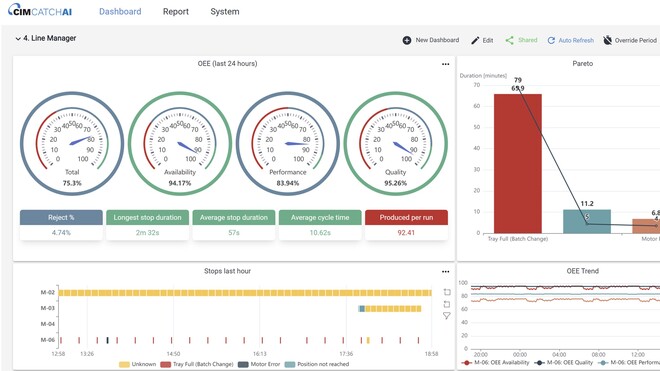

CATCH.AI Smart Data

We recognize the significance of data-driven decisions, which is why we rely on CATCH.AI by CIM. CATCH.AI is an all-in-one smart data platform that consolidates vast amounts of scattered data from equipment data silos, organizing it around events for intuitive navigation. It is a completely open system, which means you control the content of the data streams. This empowers you to make informed, data-backed decisions.

More about CATCH.AI

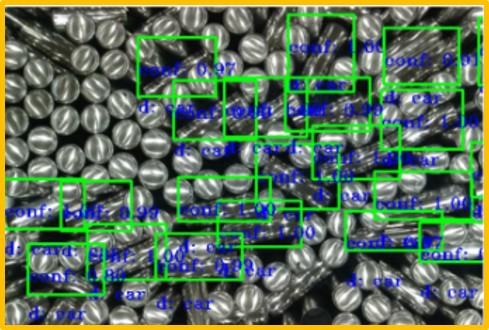

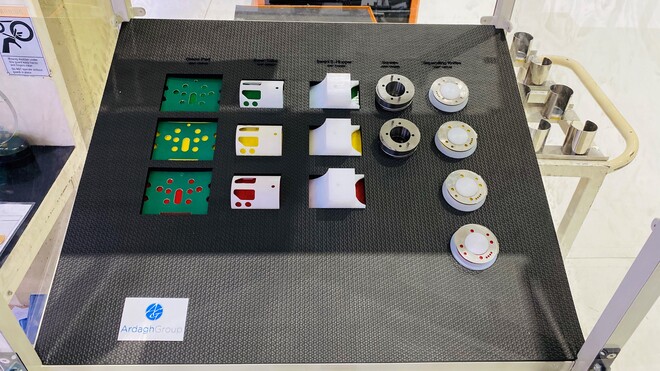

Vision System

CANLINE's automation solutions incorporate Vision Systems. These systems utilize cameras and image processing software to identify and track cans and ends as they move through the conveying system. It ensures the accuracy and quality of the conveying line and allows us to remotely identify and solve problems.

Remote Access

CANLINE's Remote Access feature allows you to diagnose issues with your automation solutions remotely. This reduces downtime significantly. We implement appropriate security measures to protect our customers' data, making remote access a secure and reliable option. Remote Access is well suited for companies with multiple locations or those operating in remote areas.

End of Life Upgrades

CANLINE offers end of life upgrades for production lines or parts of production lines to extend their lifespan and optimize their performance. By having both hardware and software engineering in-house, we can provide our customers with long-term value.

Line Control Benefits

- One partner for requirements and specifications.

- The delivered package is an integrated system from one source.

- No finger-pointing among several suppliers.

- Integral guarantee: Integrated planning and realization of

- Development resources

- Manufacturing

- Assembly

- In-house testing

- Commissioning