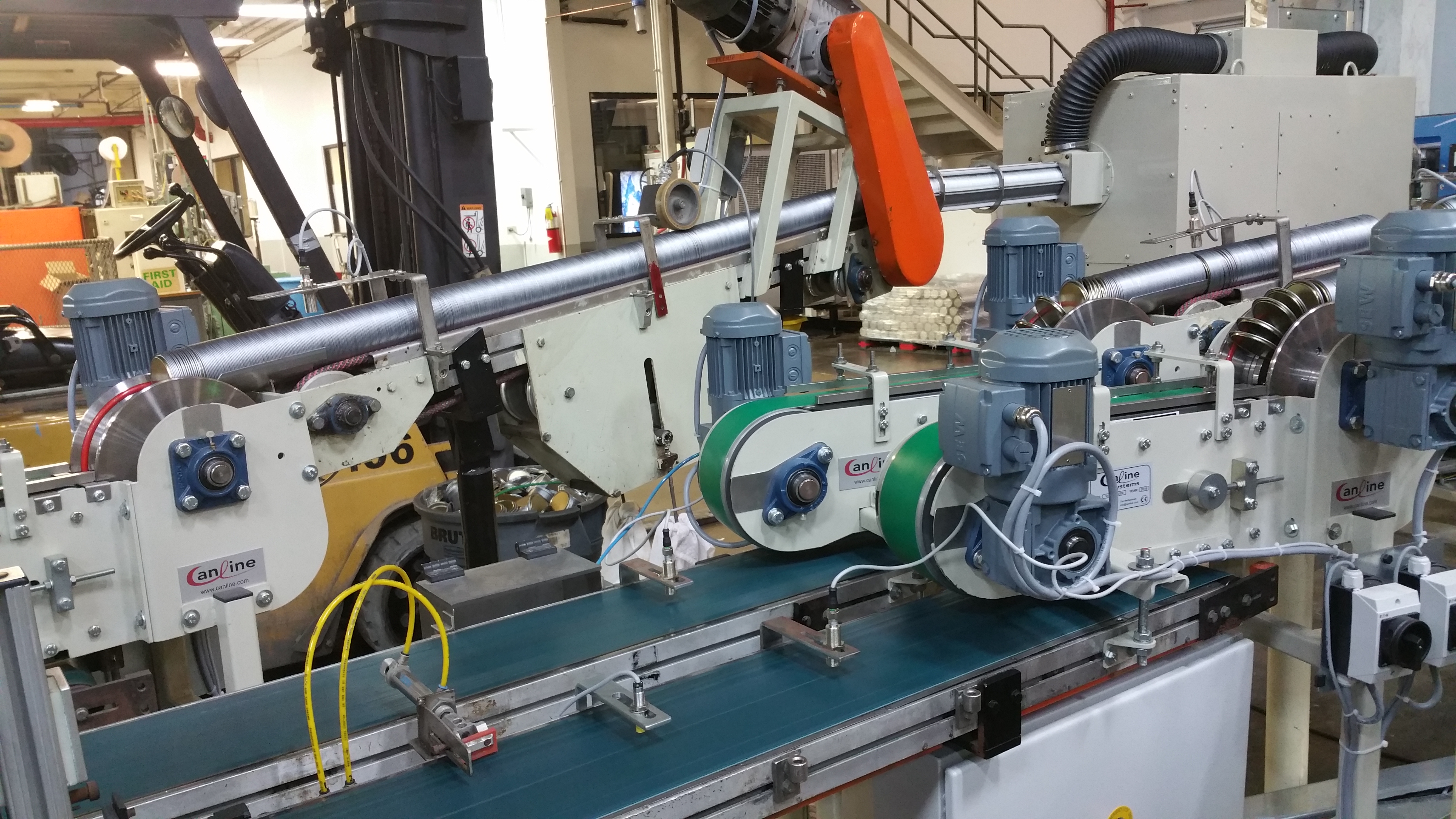

Conveying Solutions for the Food Can and End Making Industry

CANLINE specializes in tailored conveying solutions for the food can and end making industry, offering handling services for both steel and aluminum cans and ends. Metal packaging companies choose CANLINE for custom-designed, streamlined, high-volume production lines. Our focus on various can sizes and end solutions, combined with partnerships like NPB, Intralox, and Rockwell, ensures top quality and comprehensive service. Count on efficient and cost-effective line solutions at every project stage.

Sustainable Food Packaging

Both steel and aluminium cans are sustainable food packaging because they are easy to recycle. Add up that zero preservatives are required to preserve canned food, and that it only takes a few hours from crop to can, and it is very easy to understand why these cans are so popular to package food.

- Metal packaging is the most recycled packaging in Europe

- 85.5% of steel packaging and 76% of aluminium beverage cans are recycled in Europe

- Producing aluminium from recycled aluminium cans only takes 5% of the energy needed to produce new aluminium

Magnetic Components

The design and production of magnetic components for conveying makes CANLINE unique. We use magnetic forces to move and control metal cans or ends along a production line. With our custom-designed magnetic plates our customers can sort, align or separate cans or ends during the conveying process.